Automation solutions in intralogistics: an indispensable key to success

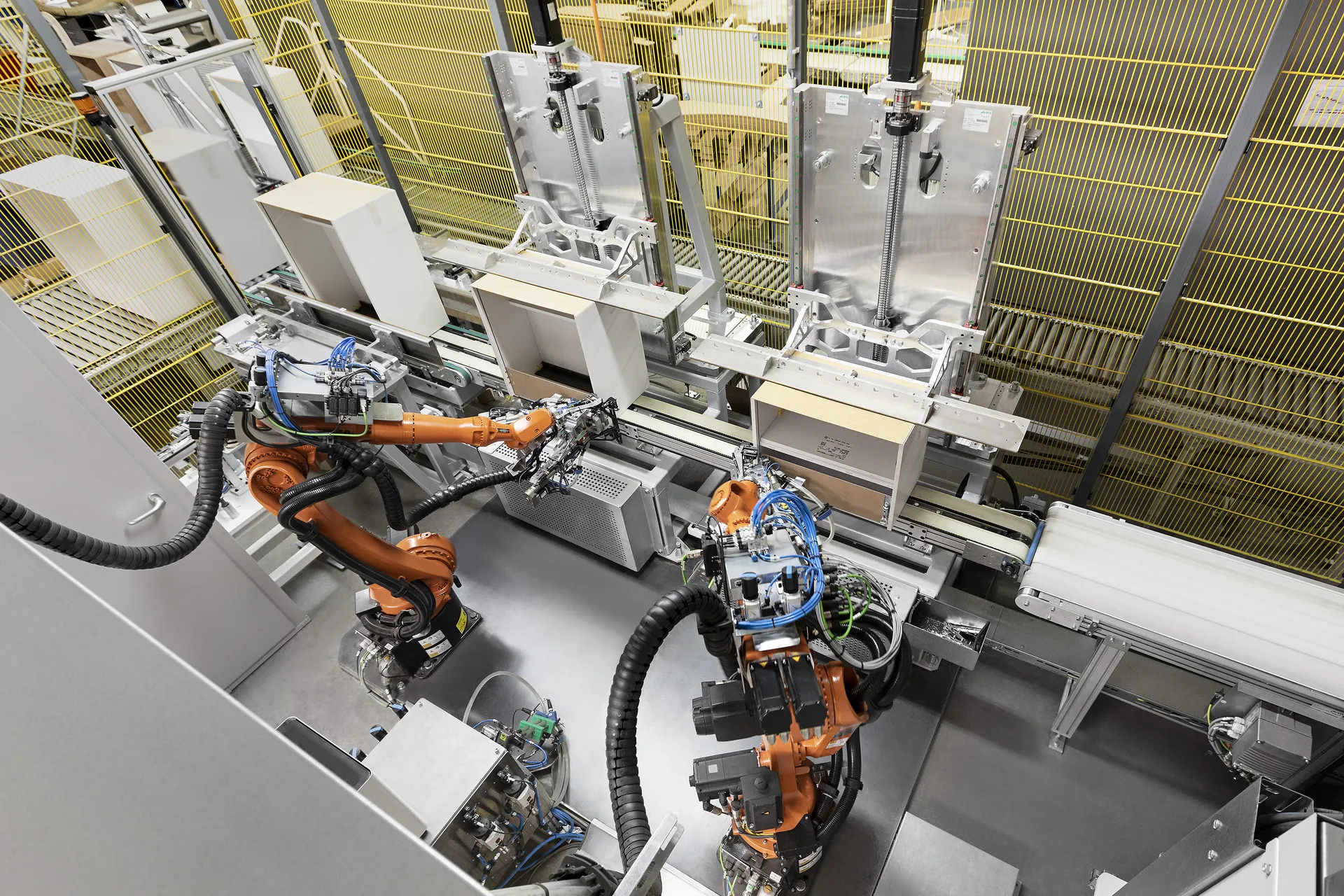

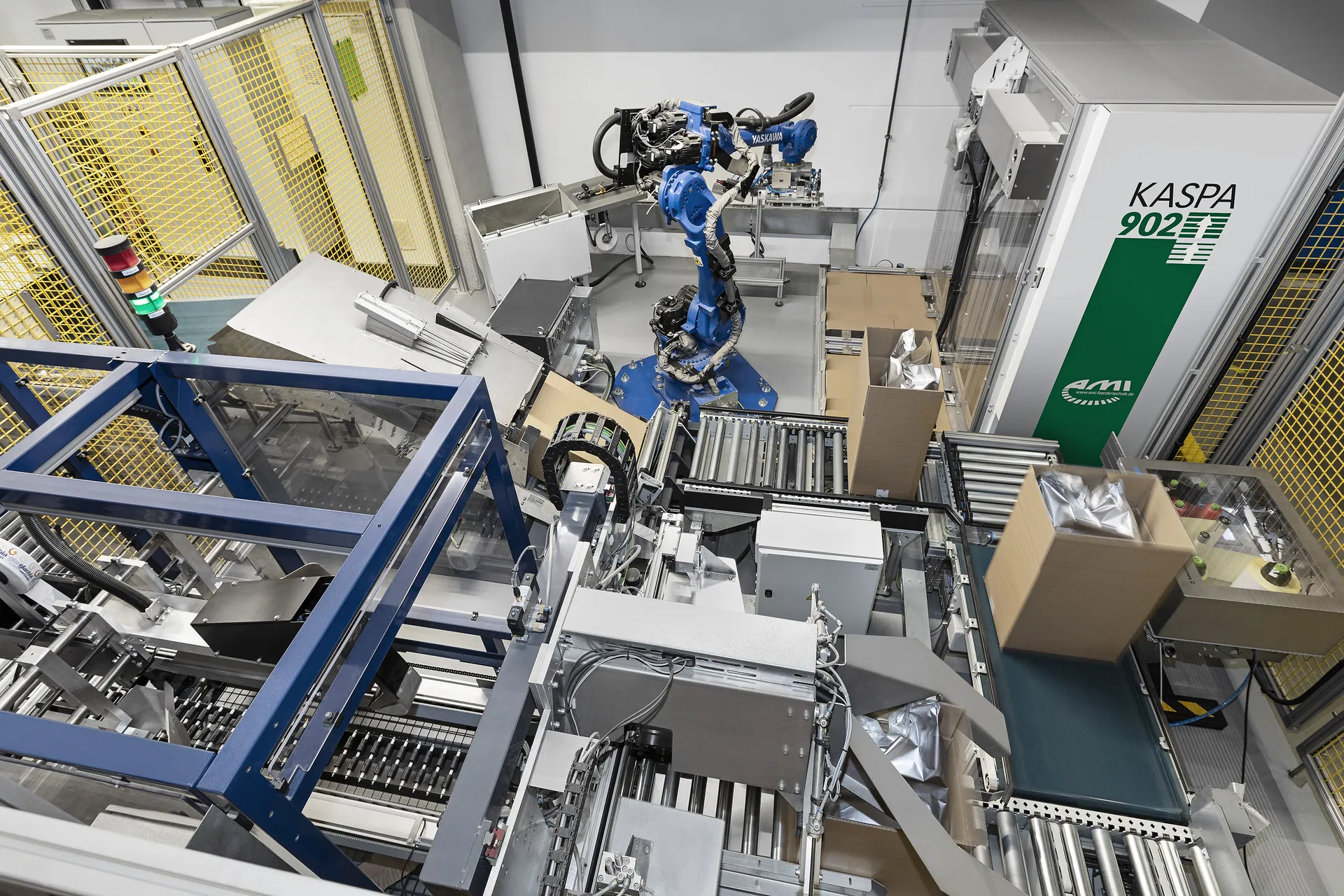

Intralogistics has evolved considerably in recent years. A decisive factor in this transformation is automation technology, which paves the way for greater efficiency, safety and cost savings. With the increasing complexity of processes and systems in production and logistics, automation solutions are becoming ever more important. In order to exploit the potential of this development, the networking of all partially and fully automated systems along the internal value chain is crucial. Smooth data exchange between the system components of conveyor and storage technology and the robot-assisted systems used in areas such as order picking, palletizing and the production process is particularly important.

Customized automation solutions for maximum efficiency and flexibility

In order to find the right level of automation for each specific project requirement, we work with our customers to develop customized solutions from a single source. By combining the right conveyor and subsystems, we achieve high performance and efficiency in the implementation of intralogistics systems or material flow systems. This avoids unnecessary interfaces and achieves maximum flexibility. The interaction of state-of-the-art control technology with our innovative conveyor systems – also tailored to individual customer requirements – guarantees optimum automation solutions. It is also possible to connect our systems to the AMI WLS warehouse logistics solution software to ensure seamless integration and efficient overall control.

What impact does automation technology have on operational processes?

Automation technology has revolutionized intralogistics and has become an integral part of modern companies. Increasing efficiency, reducing costs, improving safety, increasing flexibility and promoting sustainability are just some of the benefits. Companies that rely on automation solutions are better positioned to meet the challenges of the future and secure their competitiveness. Investments in automation technology are not just decisions for the present, but also for successful and sustainable development.

1. increase in efficiency

One of the main advantages of automation solutions in intralogistics is the significant increase in efficiency. Automated systems such as conveyor systems, sorting machines and other specialized conveyor technology move large quantities of goods in the shortest possible time and sort them efficiently. Throughput is maximized and throughput times are reduced. This optimizes supply chains and improves customer service. Automation standardizes workflows helps to avoid bottlenecks, resulting in continuous improvement of operational processes.

2. cost savings

The introduction of automation solutions in intralogistics leads to considerable cost savings. Even if the implementation initially involves an investment, this quickly pays for itself through the optimization of resource utilization, the reduction in labour costs and the higher efficiency of the automated systems. Automation increases performance and lowers operating costs, resulting in sustainable cost reductions.

3. improvement of safety

Automation technology makes a significant contribution to reducing the risk of accidents and making both the working environment and processes safer. Automated systems take over dangerous tasks such as lifting heavy loads or working in high-risk environments. This not only protects employees, but also ensures greater stability and reliability of processes. At the same time, automated monitoring systems enable continuous control of operational processes so that potential hazards can be identified and eliminated at an early stage.

4. flexibility and scalability

Another advantage of automation technology in intralogistics is its increased flexibility and scalability. Modern automation systems have a modular structure and can be easily adapted to changing requirements. This enables companies to react quickly to market changes and expand their capacities as required. Especially in times of peak demand, such as during holidays or promotions, automation solutions can ensure smooth operations. In addition, companies can continuously optimize and adapt their processes by integrating data analysis.

5. sustainability

Another key advantage of automation solutions is their positive impact on sustainability in intralogistics. By optimizing work processes and improving the use of resources, companies can work more efficiently. Automated systems are more energy-efficient and therefore help to reduce the ecological footprint. Automation also ensures more precise inventory management, which prevents overproduction and conserves resources.

FAQ:

What role does automation technology play in the optimization of logistics processes?

Automation technology plays a crucial role in optimizing logistics processes by increasing efficiency, accuracy and speed. Automation solutions enable more precise control of the flow of goods, minimize manual intervention and increase flexibility. By using automated systems, companies can make their warehousing and transportation processes faster, safer and more cost-effective.

What advantages do automation solutions offer?

Automation technology offers numerous benefits, including a significant increase in efficiency, cost reductions, improved safety by taking over hazardous tasks, greater flexibility thanks to adaptable systems and a positive contribution to sustainability through optimized use of resources and energy-efficient processes. Automation solutions help to realize all these benefits and ensure the competitiveness of companies.