AMI conveyor systems – The basis for your intralogistics

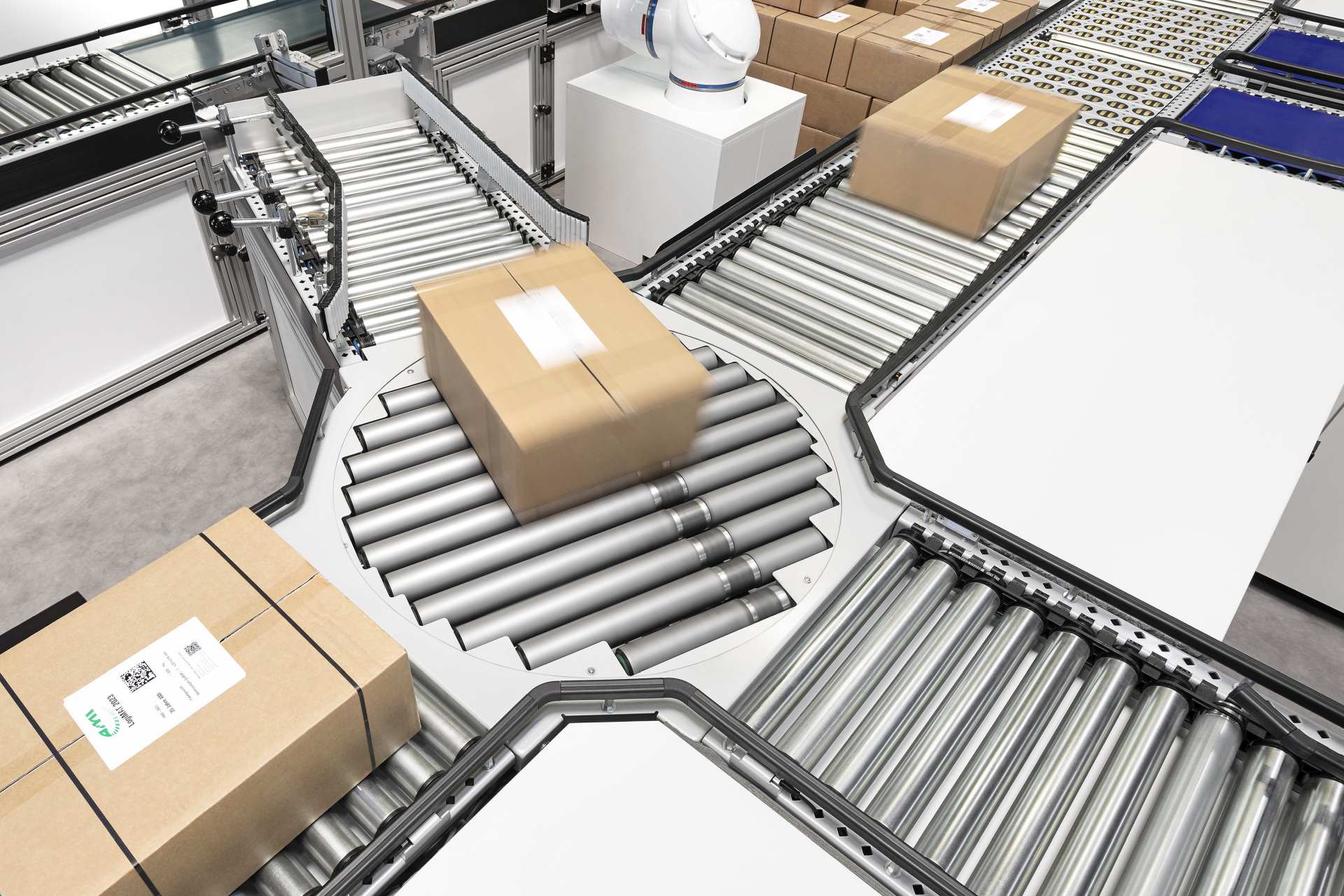

Modern conveyor systems are crucial for efficient logistics processes and enable goods and materials to be transported smoothly and on time. AMI offers reliable, high-quality solutions – from simple conveyor systems to customized special solutions in conveyor technology. With individually adapted systems, we optimize your internal material flow and increase the efficiency of your entire intralogistics.

Versatile conveyor systems for your requirements

We offer a wide range of conveyor systems that can be flexibly adapted to your needs:

Light conveyor technology

Manual and powered systems, such as roller conveyors and belt conveyors

Heavy-duty conveyor technology

Systems for heavy and bulky goods, e.g. heavy-duty roller conveyors and chain conveyors

Automated systems

Fully automated solutions, such as robot-assisted units and production lines

Special solutions

Individually developed system solutions for your specific requirements

Optimal solutions for your logistics processes

Our conveyor systems adapt flexibly to your logistics processes to maximize your efficiency gains and minimize costs. These include conveyor systems on smooth-running rollers, belt and roller conveyors, vertical conveyors and automation technology such as robotics. These solutions not only increase your efficiency in picking, sorting and packing, but also help to reduce your operating costs and improve your material flow.

Focus on sustainability and efficiency

With modern conveyor systems and innovative conveyor technology, you can reduce the manual workload and improve the sustainability of your processes. AMI relies on energy-efficient drive technologies, such as 24-volt technology, which reduce your electricity costs while offering high performance. We also integrate intelligent networks and software solutions that make your intralogistics and conveyor technology even more efficient.

AMI - Your partner for conveyor systems

Whether it’s conveyor systems or storage systems, light or heavy loads, manual or automated – AMI offers you the perfect system solution for your intralogistics. Benefit from our many years of experience, top quality and a partnership-based approach to planning and implementing your projects.

FAQ:

What types of support systems are there?

There are different types of conveyor systems, which are divided into different categories depending on the requirements and areas of application:

- Lightweight conveyor technology: Conveyor systems for smaller, lighter goods such as packages, boxes or cartons. Examples include roller conveyors and belt conveyors.

- Heavy-duty conveyor technology: Systems for transporting heavy and bulky goods such as machine components and pallets. These include chain conveyors and heavy-duty roller conveyors.

- Automated conveyor systems: Fully automated conveyor solutions that make production and logistics more efficient. Examples include robot-assisted units and fully automated production lines.

- Special solutions: Individually developed systems that are specially tailored to the needs of customers and specific industry requirements, e.g. for the pharmaceutical industry, mechanical engineering or food processing.

How do AMI's conveyor systems contribute to increasing efficiency?

AMI’s conveyor systems contribute to increasing efficiency in various ways:

- Optimization of the material flow: The use of tailor-made conveyor systems optimizes the internal material flow, resulting in a more efficient organization and faster processes.

- Relief for employees and cost reduction: Automated and hybrid conveyor systems take over repetitive tasks, relieving employees of monotonous activities and allowing them to concentrate on value-adding tasks. This increases productivity and reduces operating costs in the long term by saving energy and labor resources.

- Improvement of logistics processes: Conveyor systems such as roller conveyors and belt conveyors speed up specific logistics processes such as picking, sorting and packing, resulting in more efficient operations overall.

Which goods can be transported with AMI conveyor systems?

AMI’s conveyor systems can be used to transport a wide variety of goods, including:

- Small and light goods: such as parcels, cartons, individual parts and smaller components that are frequently used in warehouse logistics, order picking or shipping.

- Medium-heavy goods: Components, workpieces and products that are moved using chain conveyors or pallet conveyors, e.g. in production or assembly.

- Heavy loads: Machine components, steel beams and pallets that are transported using heavy-duty conveyor technology, particularly in the automotive, casting and mechanical engineering industries.

- Sensitive and specialized goods: electronic components, pharmaceutical products or foodstuffs that are moved with special solutions for safe and gentle transport.

Customers can also submit individual requests for special conveyed goods that are tailored to their specific requirements and processes.