Order picking? Let’s make it smarter. The SMART-FLEXDEPOT

With the SMART-FLEXDEPOT, you can speed up your order picking – secure, scalable and integrated. State-of-the-art technology combined with modular design and intelligent control for maximum performance and flexibility.

The SMART-FLEXDEPOT – The new dimension in automated order picking

The SMART-FLEXDEPOT models in detail

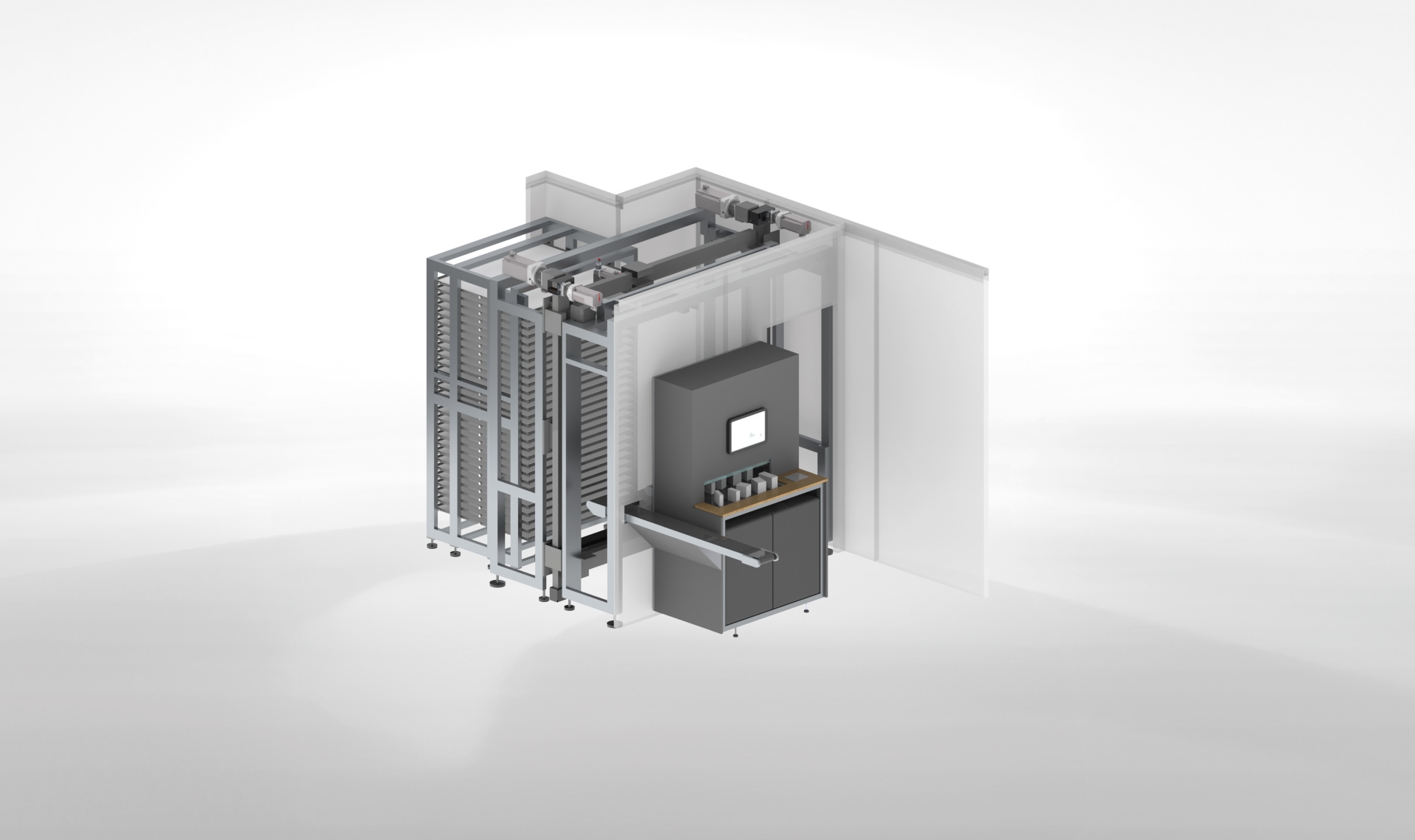

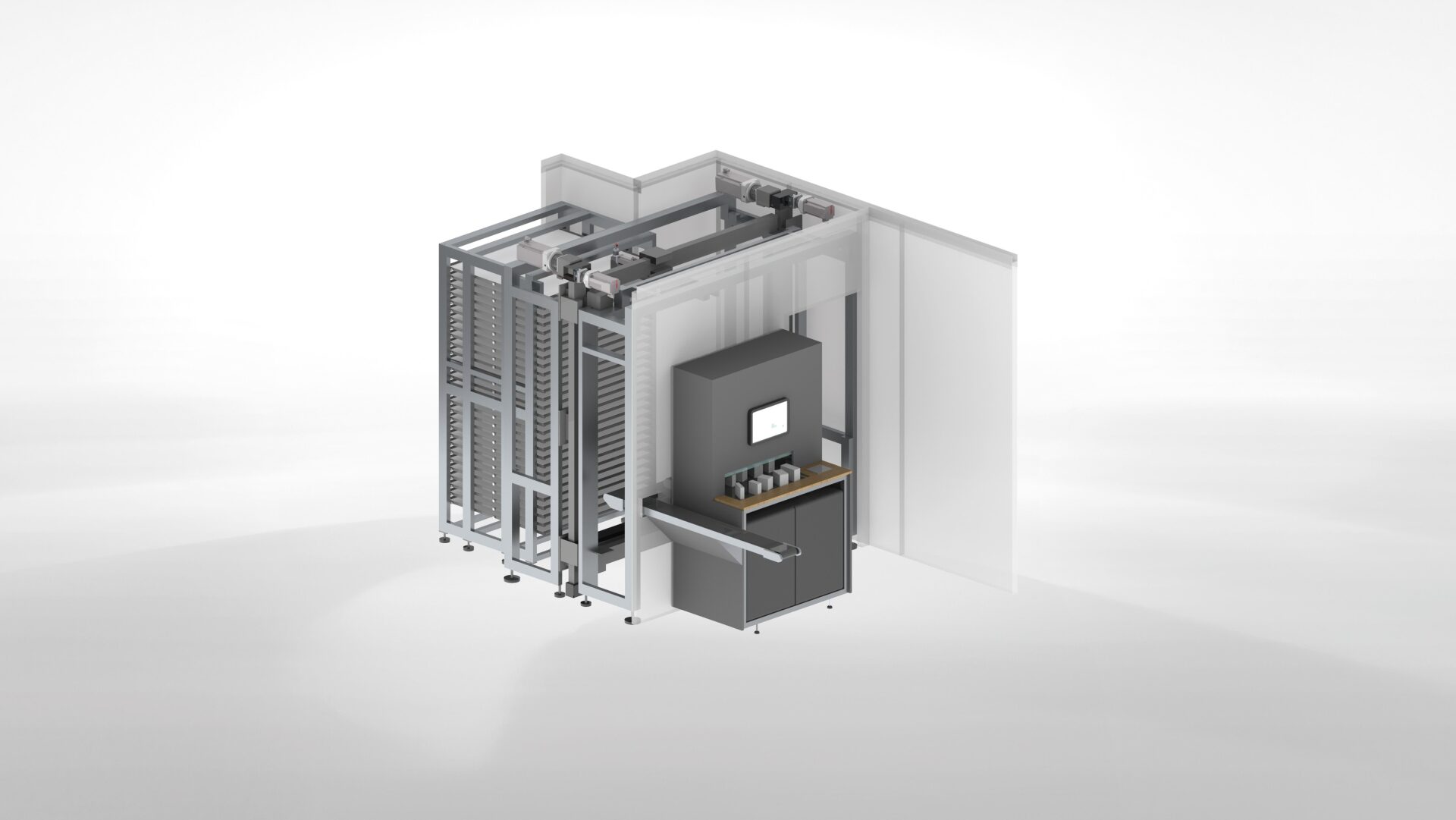

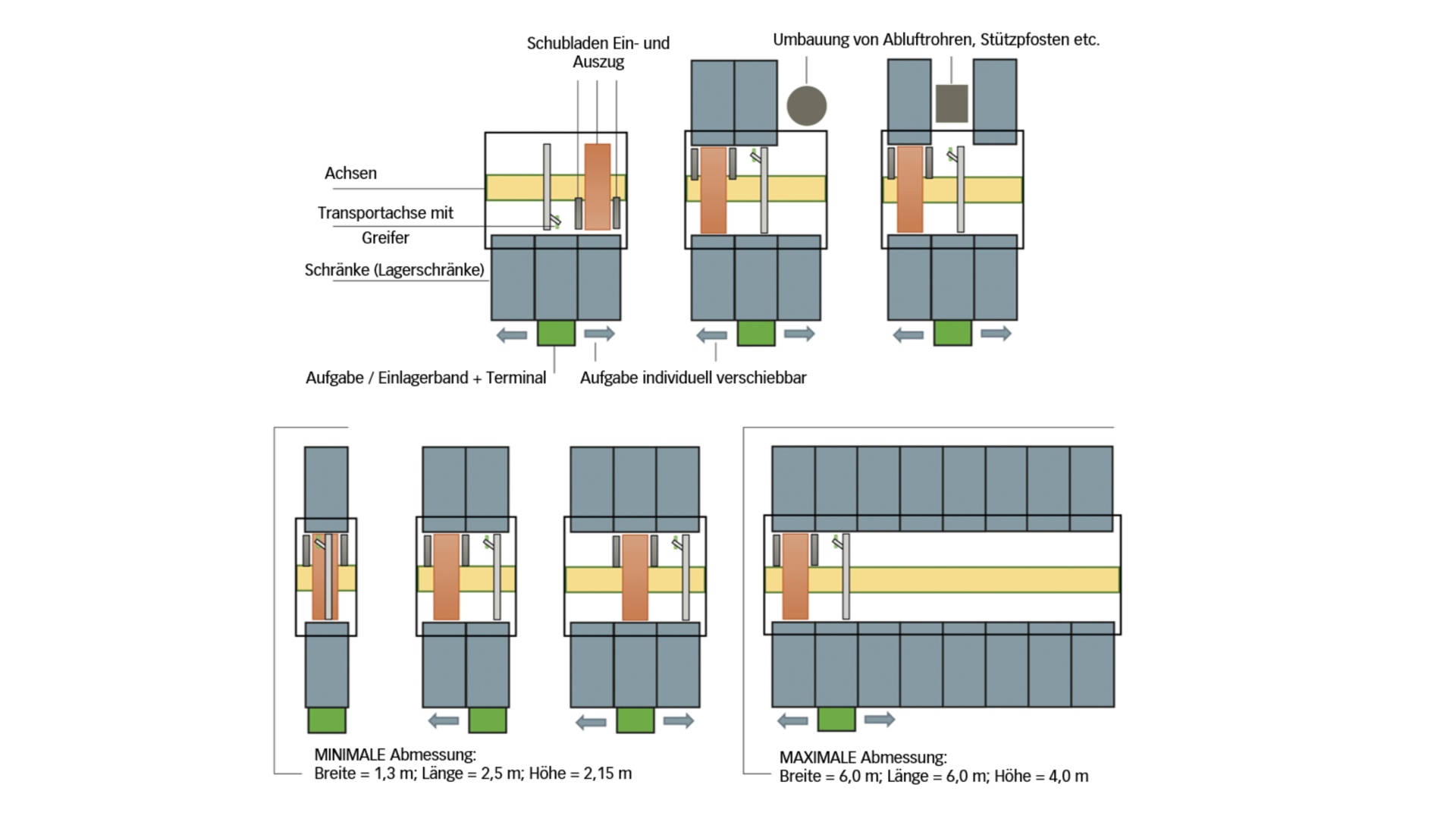

MODULAR CONSTRUCTION – INDIVIDUAL CUSTOMIZATION

- Minimum dimensions: Width = 1.3 m | Length = 2.5 m | Height = 2.15 m

- Maximum dimensions: Width = 6.0 m | Length = 6.0 m | Height = 4.0 m

Whether confined spaces, low ceilings, chimney flues, landings, wall openings or disruptive exhaust air pipes – the SMART-FLEXDEPOT can be perfectly integrated into existing building structures. The modular system architecture not only enables optimum use of space, but also creates real structural freedom. This means that the system can be easily integrated into both new and existing buildings – without costly conversion work or restrictions in terms of function and accessibility.

The result: a sophisticated, space-saving and future-proof solution that fits seamlessly into your infrastructure and can be expanded or adapted at any time.

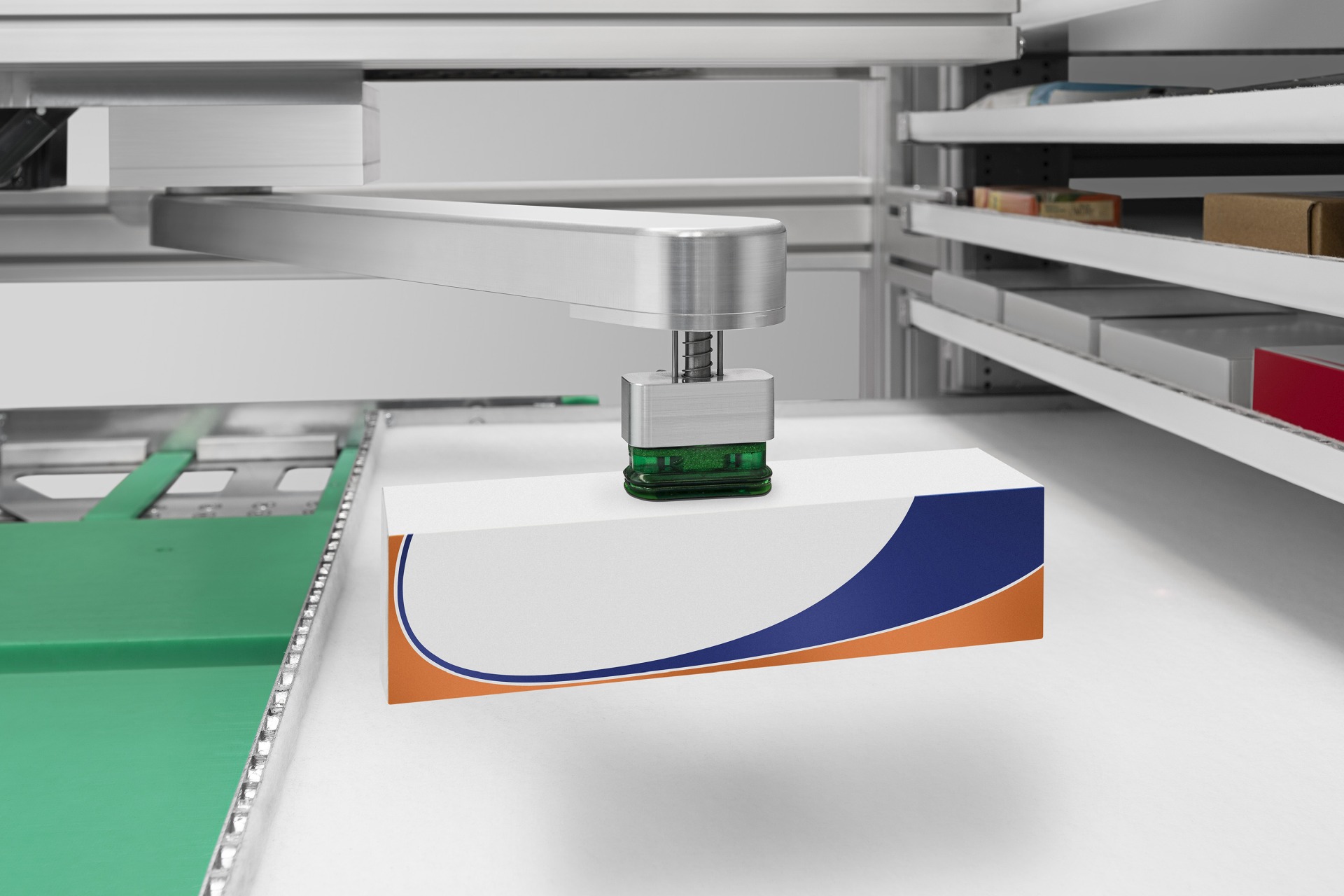

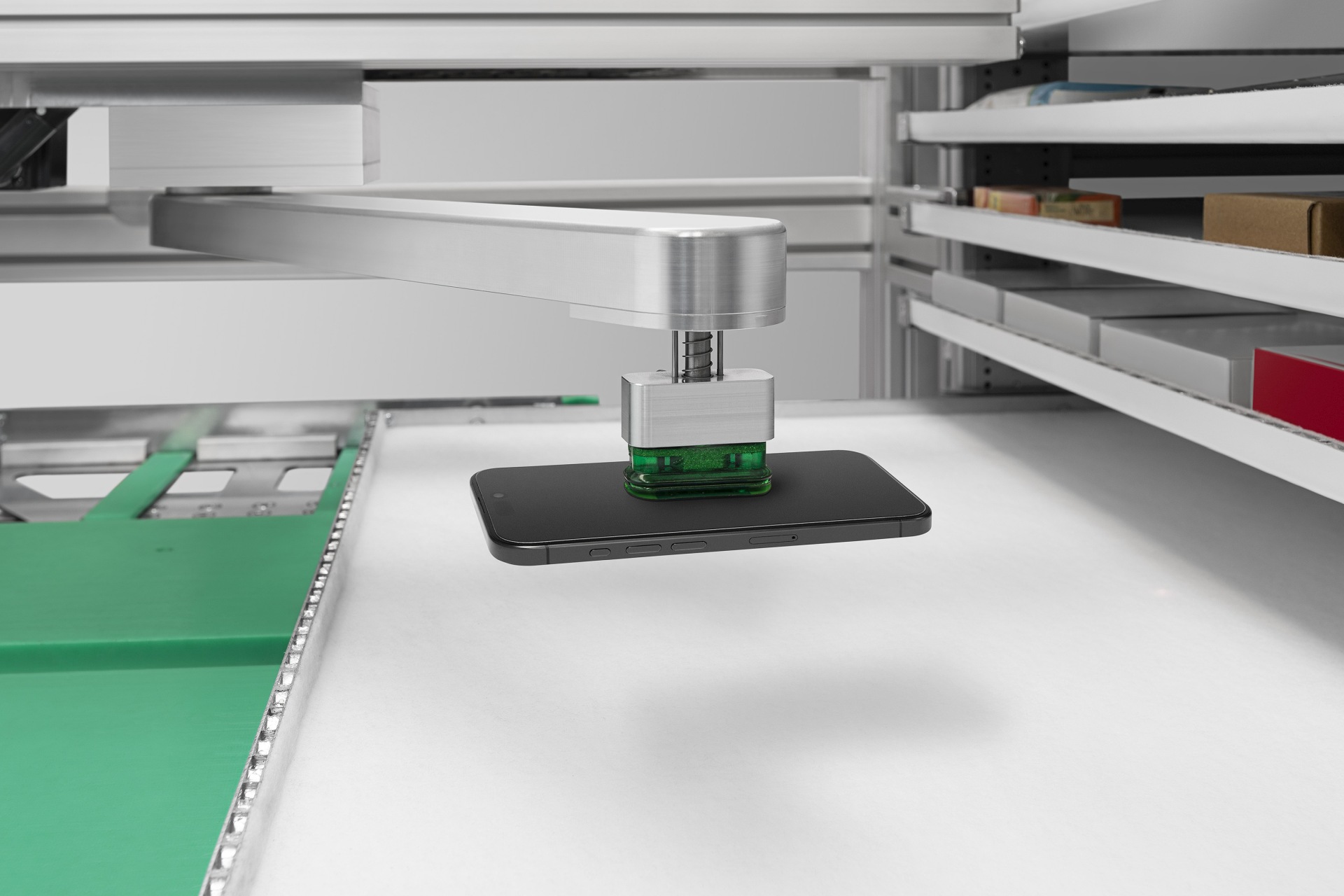

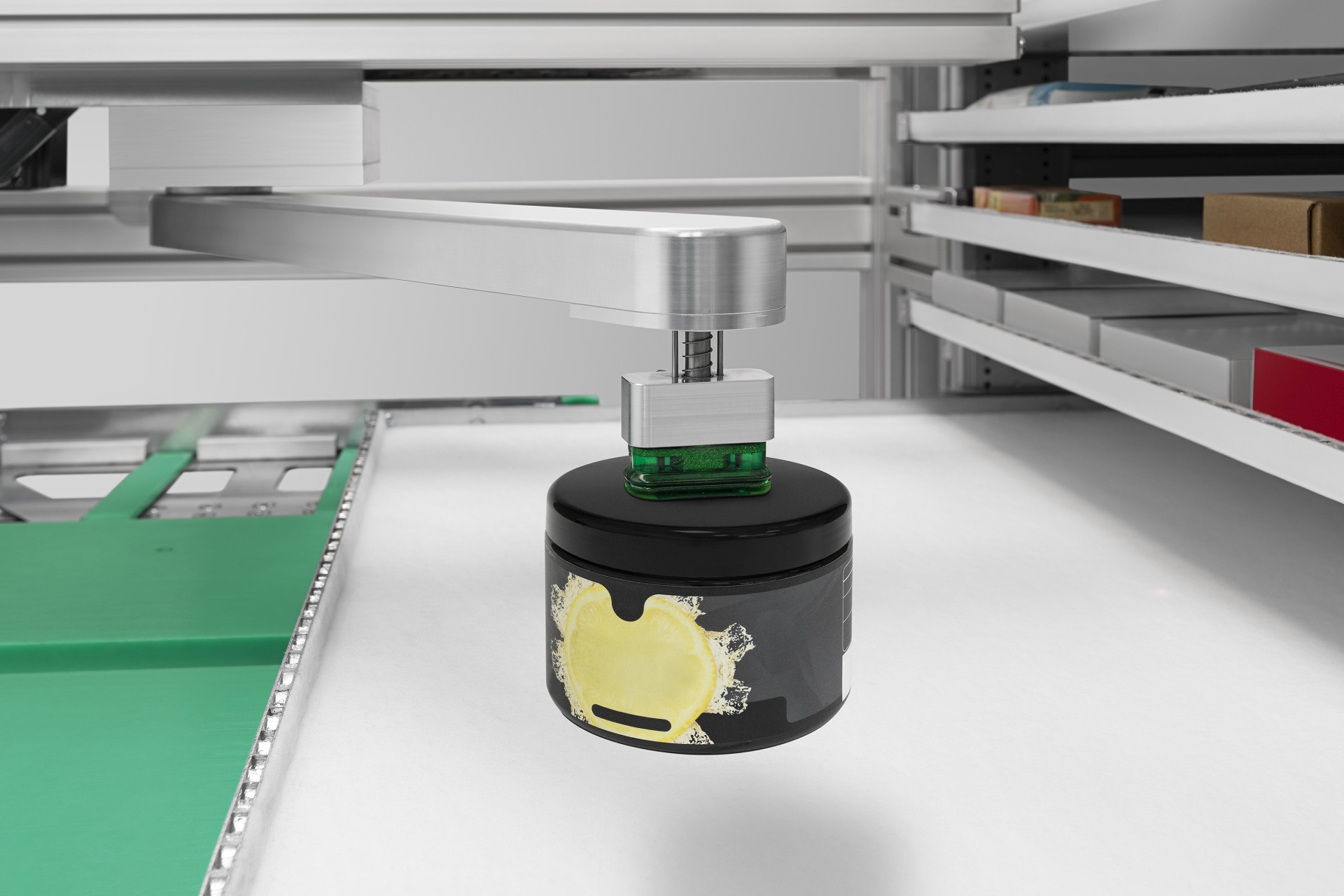

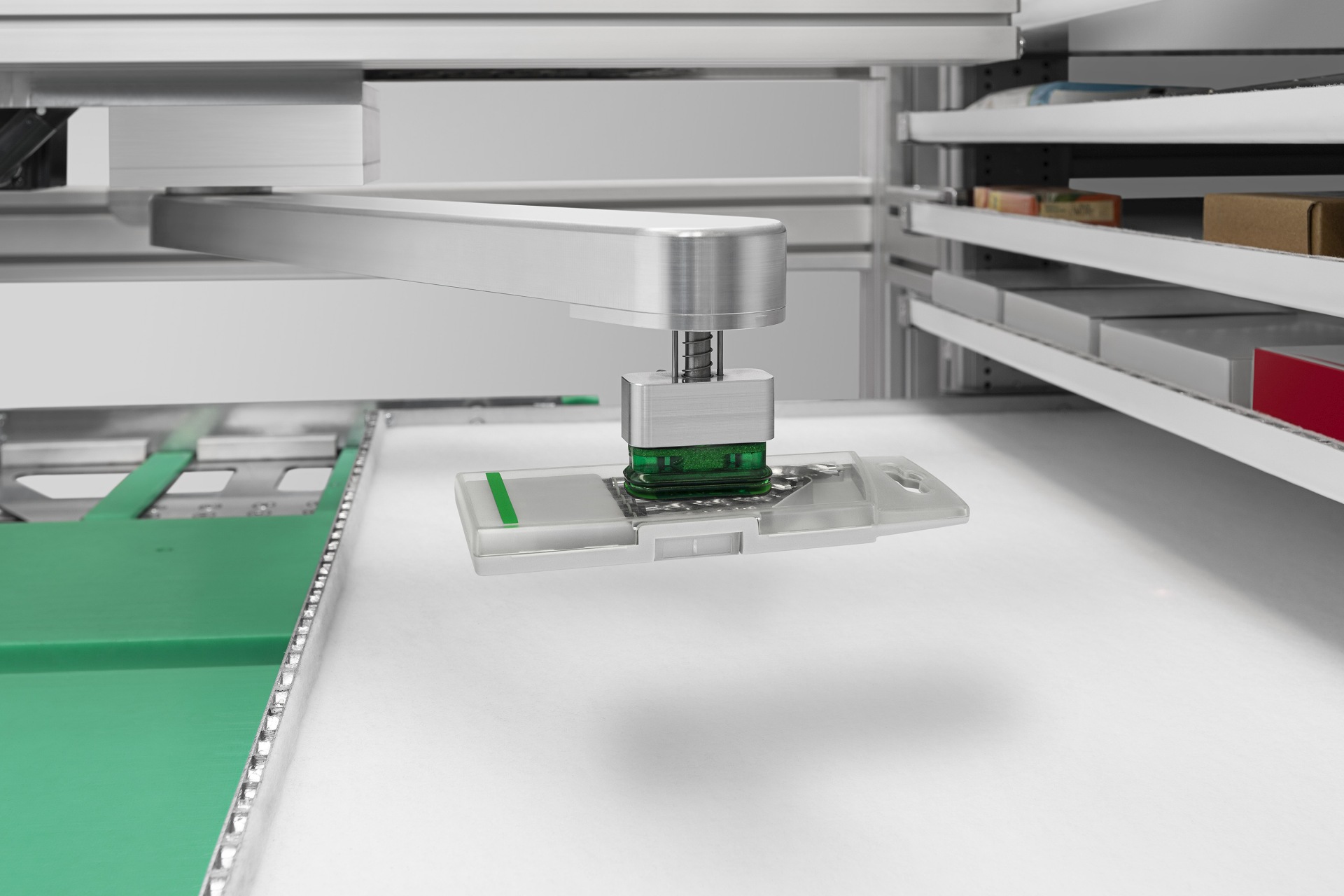

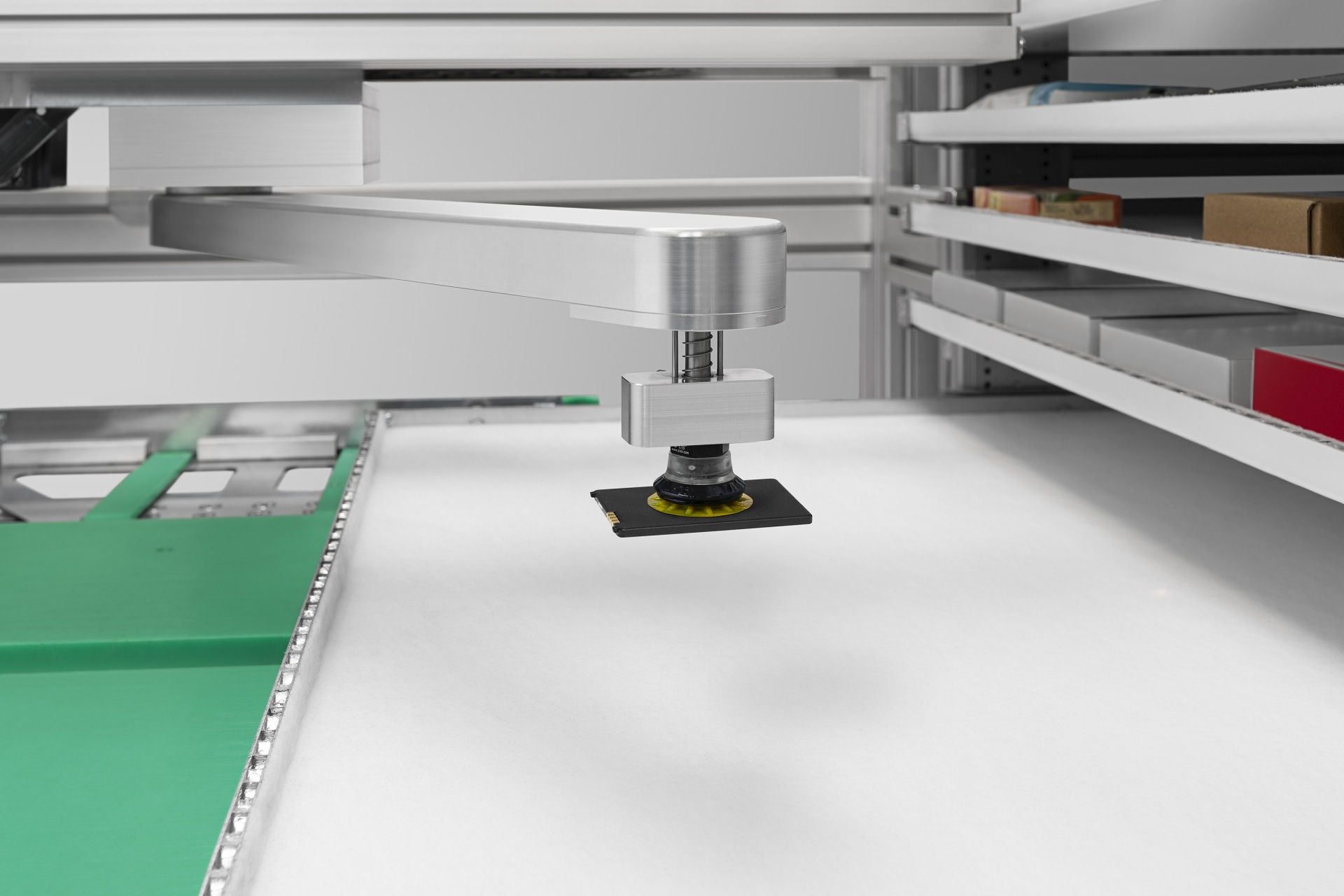

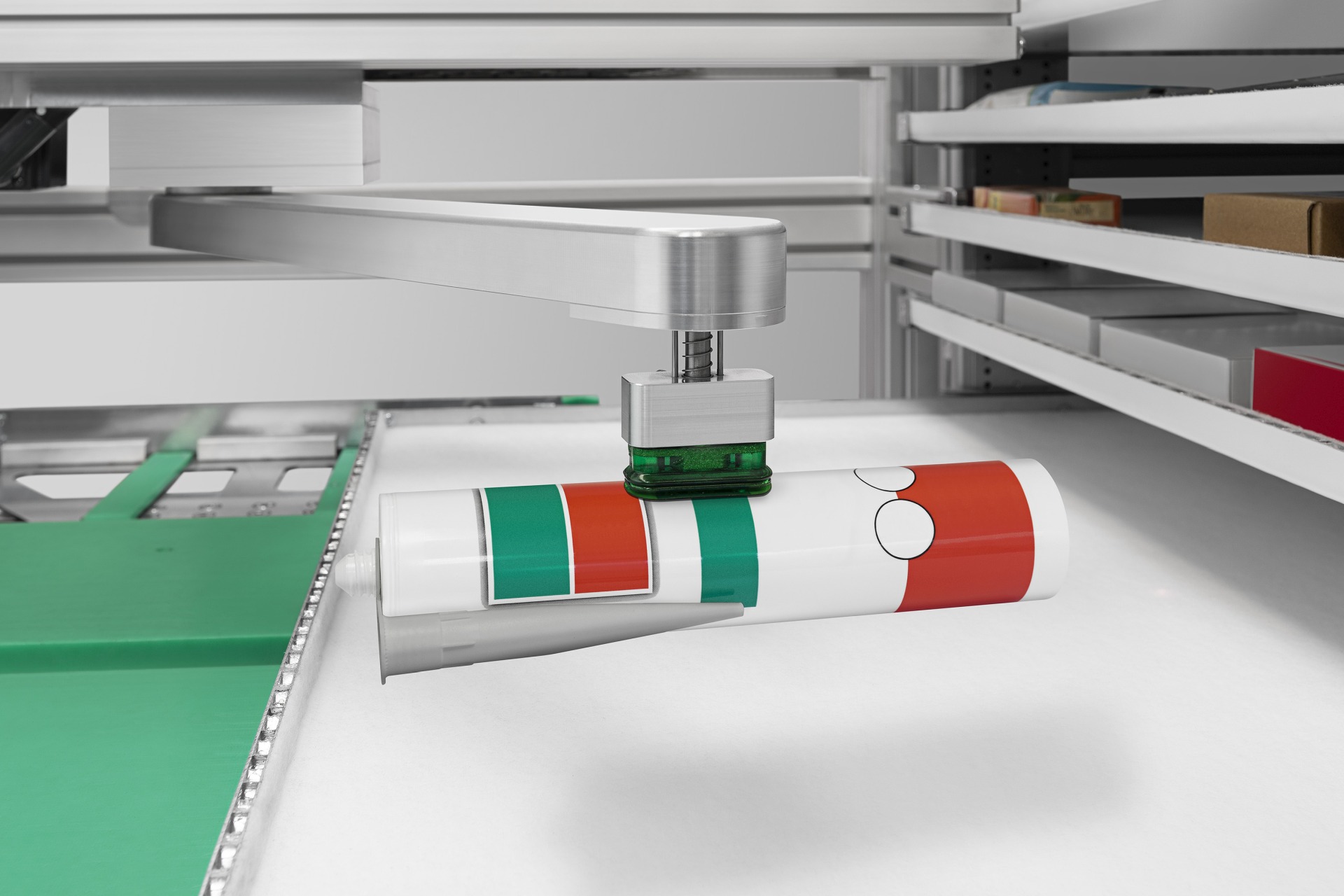

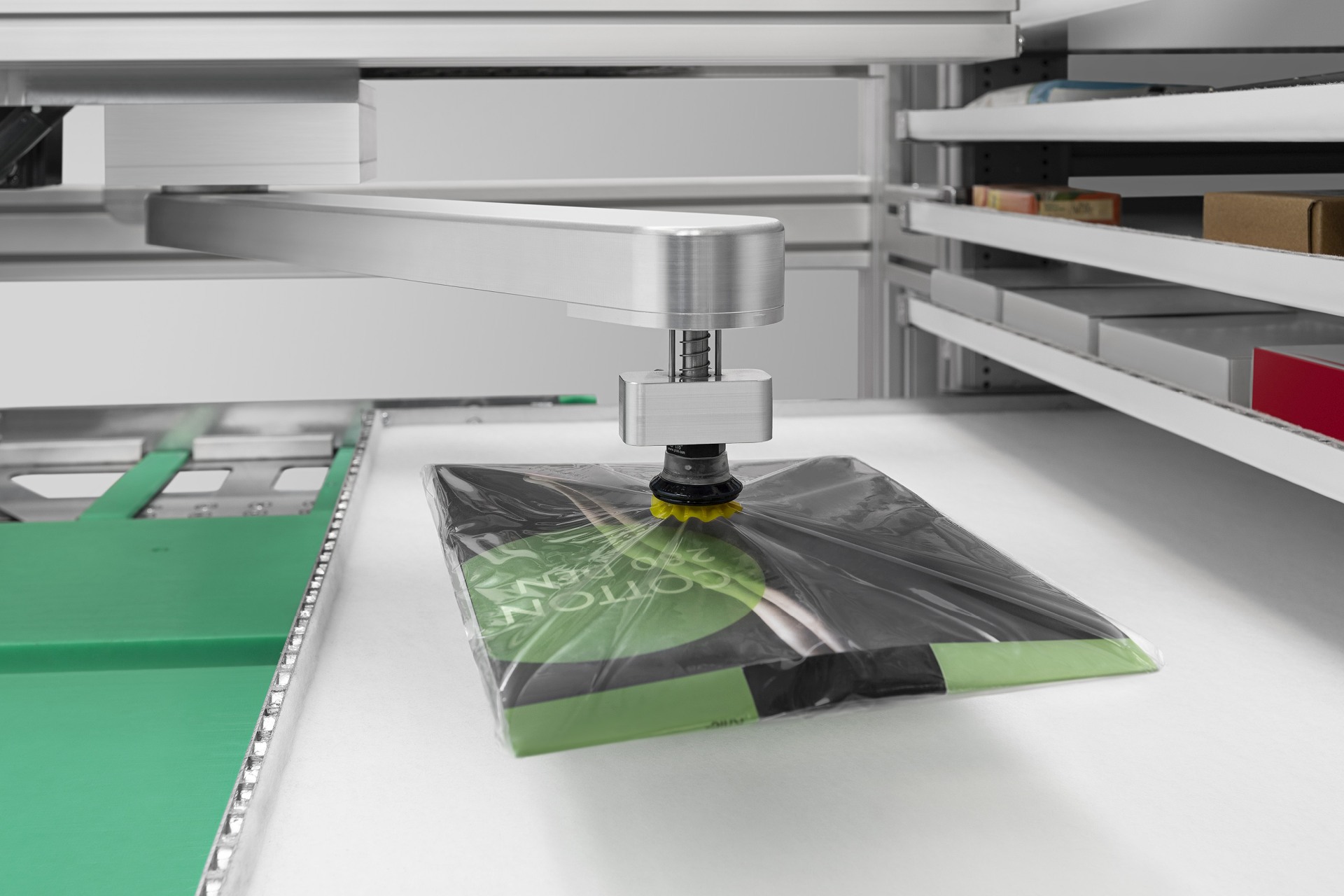

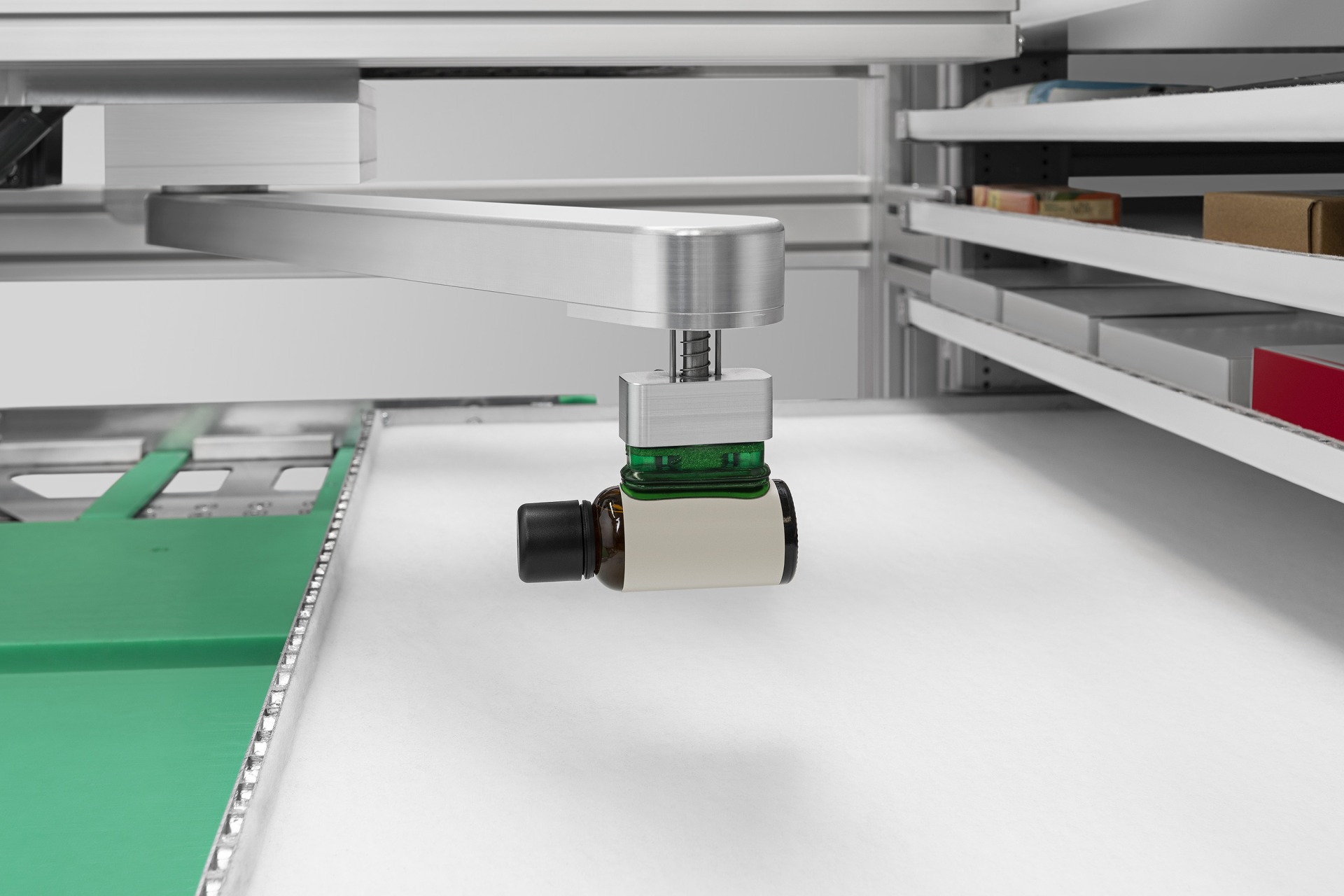

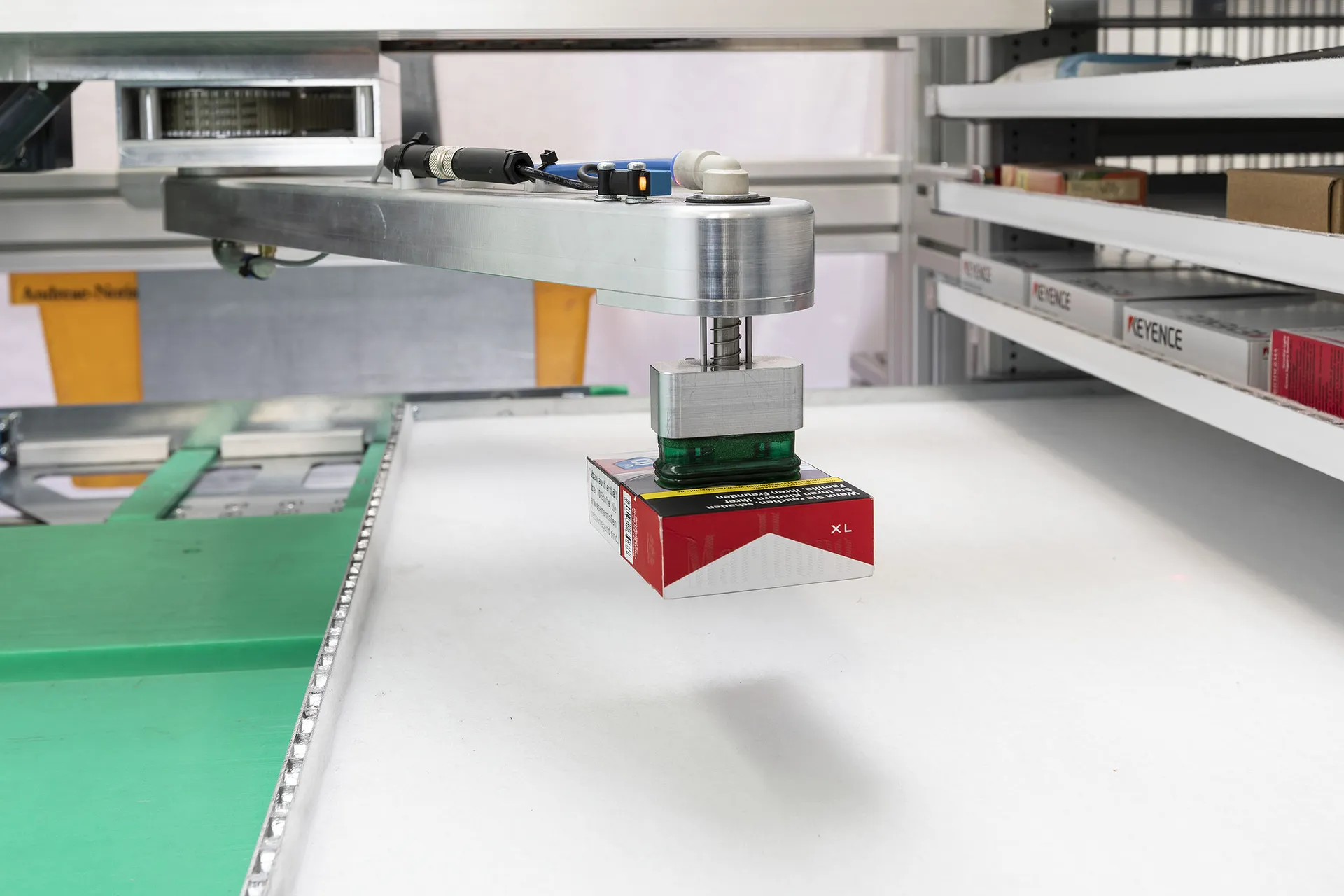

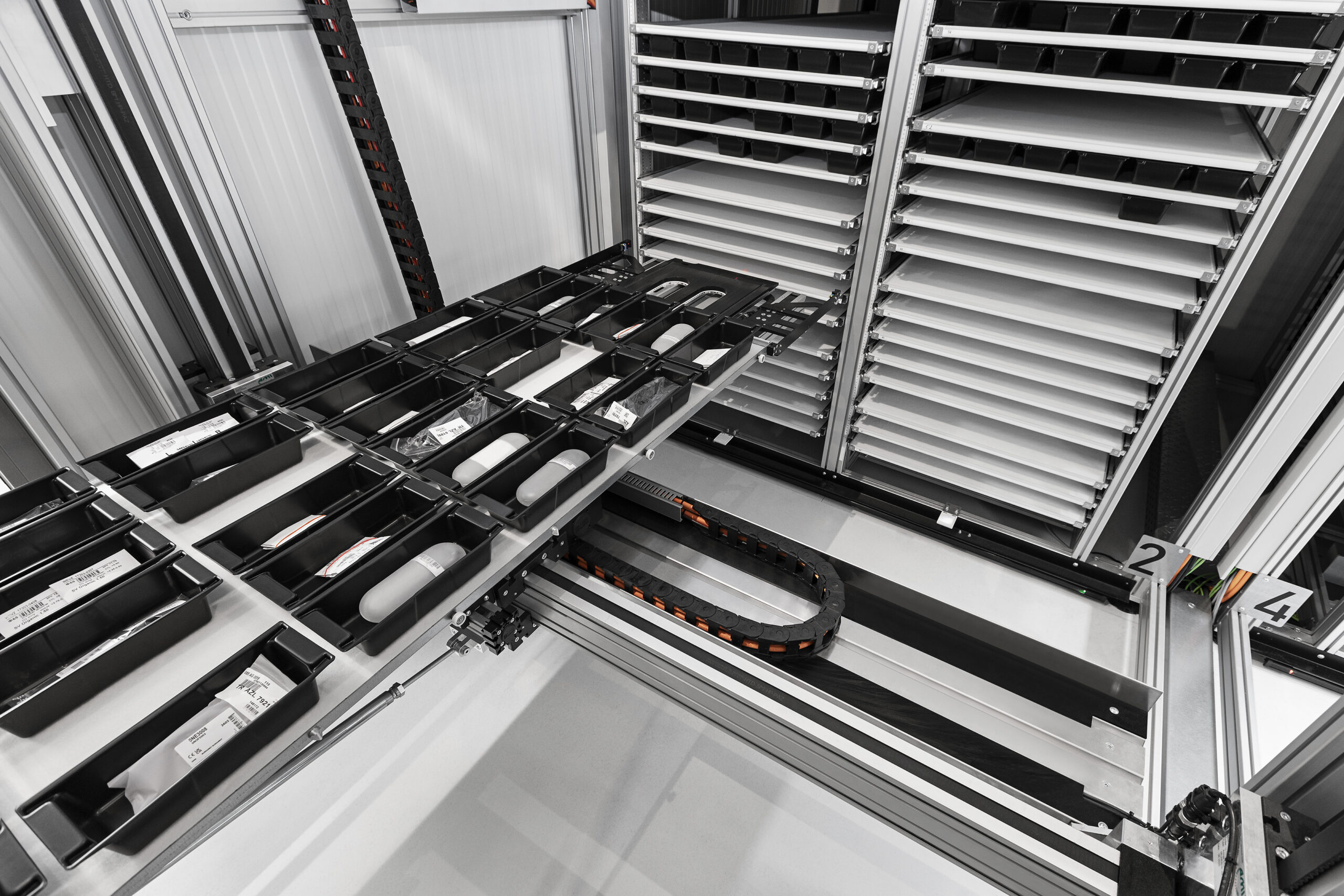

Everything under control: the AMI gripper system in the Smart-FlexDEPOT

Gripping with precision – versatility in action

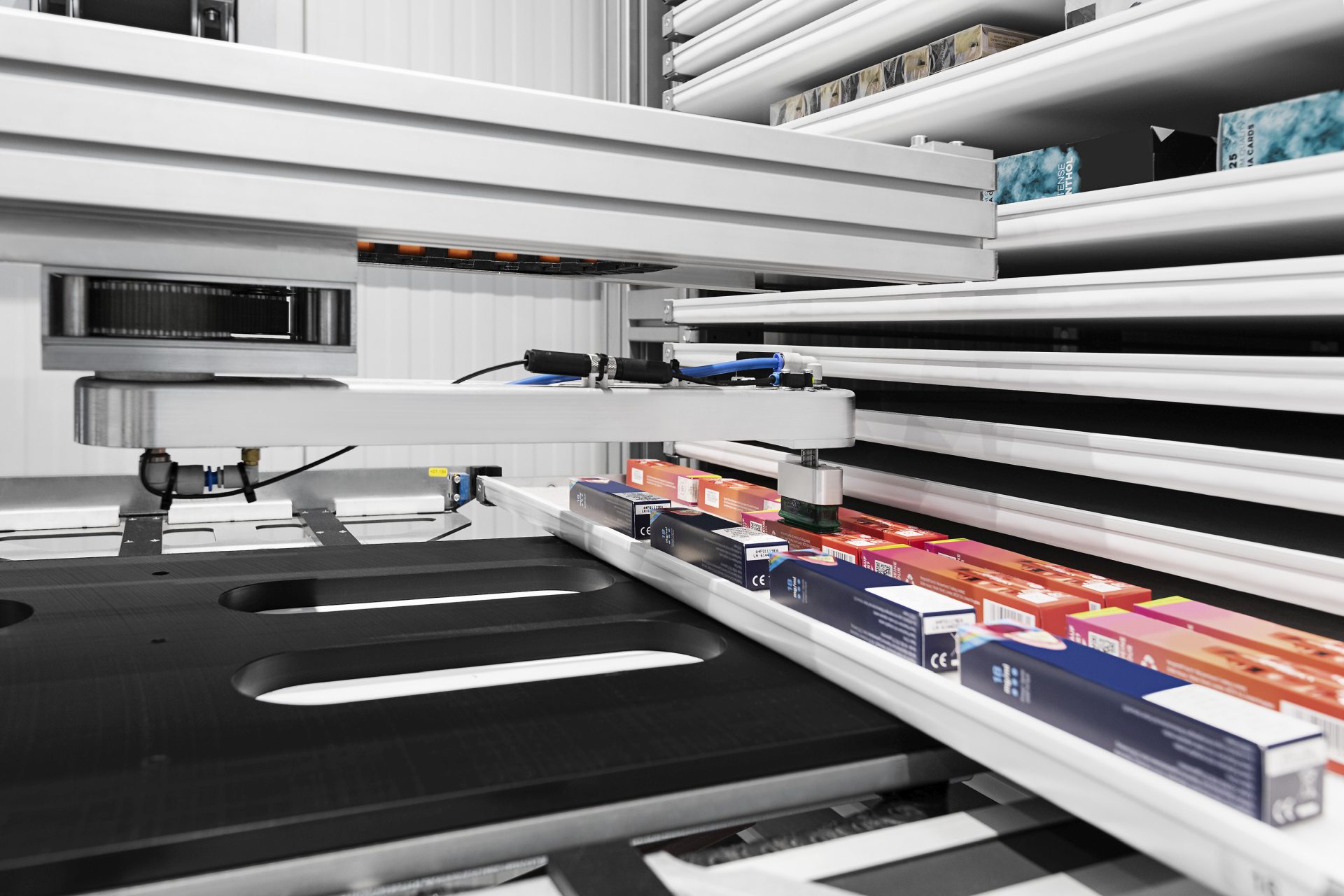

Intelligent load carrier technology for perfect order picking

The load carriers are made of lightweight, rigid materials used in aviation technology and guarantee high stability and durability. The height categories of the load carriers can be automatically adapted to changes in the product range without the need for user intervention. This enables the system to adapt flexibly and quickly to changing requirements and ensures a high level of efficiency throughout the entire storage process.