Order picking machines – customized solutions for your logistics

Innovative automated order picking systems from AMI Förder- und Lagertechnik GmbH help to increase efficiency and precision in numerous industries. Our picking systems range from simple manual systems to fully automated picking machines and thus cover a wide variety of requirements. With many years of experience in the planning, development and implementation of intralogistics solutions, we supply customized systems that are perfectly tailored to the specific needs of your company – regardless of industry or company size.

System advantages of our order picking systems:

Increased efficiency

Through the targeted use of the Smart-FlexDEPOT, we optimize the speed and accuracy of your picking machines. This leads to a reduction in picking time and improved resource utilization.

Optimization

Our picking systems help to increase accuracy. With modern technologies such as barcode scanners and pick-by-light systems, we ensure that every product is picked correctly and quickly.

Flexibility

Whether for small or large quantities, our picking machines adapt flexibly to your requirements. From single item picking to high-speed orders, we offer the right solution for every situation.

Economic efficiency

By automating processes and increasing productivity, our automated order picking systems reduce operating costs and make the material flow more efficient.

Regardless of whether you need a simple order picking machine or a sophisticated, fully automated order picking system, AMI Förder- und Lagertechnik GmbH offers the right technology to make your logistics processes more efficient and profitable. Our order picking machines are characterized by high reliability, simple integration and a future-proof orientation that enables you to optimize your intralogistics in the long term and adapt to future requirements.

Increasing efficiency in the industry

Our automated order picking systems are not only used in warehouse and retail logistics, but also in industry, where they help to increase efficiency and automate production processes. By using our picking systems in industry, companies can optimize their production processes, reduce the error rate and increase productivity. Our solutions offer tailor-made adaptations to the specific requirements of production and support automation in various production areas.

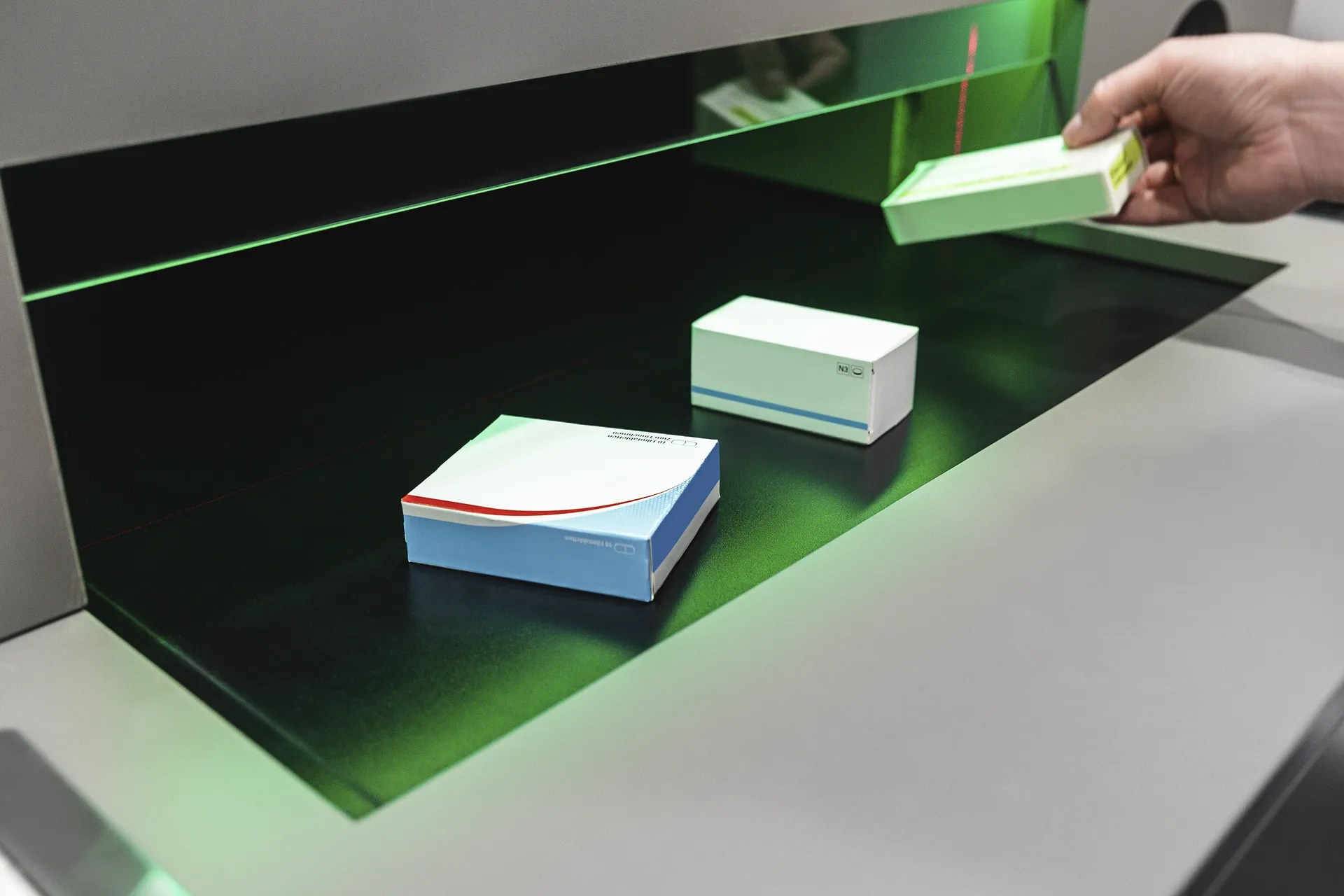

Optimization in pharmacies and medical practices

Our automated picking systems are also used in pharmacies and doctors’ surgeries to make the picking and management of medicines more efficient. Our picking systems enable pharmacies to optimize the flow of materials, minimize errors and ensure accuracy when dispensing medication. Thanks to the high speed of our machines, pharmacies with automated processes increase the efficiency of their warehousing and save valuable time.

With a high level of expertise and innovative technology, we ensure that your warehouse processes are always up to date. Rely on AMI’s solutions to take your logistics to the next level.

Our order picking systems at a glance

AMI Förder- und Lagertechnik GmbH offers you customized order picking systems that are designed for maximum efficiency and precision. With solutions such as the Smart-FlexDEPOT Classic, the Smart-FlexDEPOT Premium and the High-SpeedDEPOT, we cover a wide range of requirements in a variety of industries, from warehousing and logistics to production, retail and e-commerce. Our picking machines optimize your picking processes, increase speed, reduce errors and maximize material flow. Easy integration and high scalability make our solutions ideal for companies that want to make their logistics processes efficient and future-proof.

The SMART-FLEXDEPOT – The new dimension in automated order picking

Innovative automated order picking systems from AMI Förder- und Lagertechnik GmbH help to increase efficiency and precision in numerous industries. Our picking systems range from simple manual systems to fully automated picking machines and thus cover a wide variety of requirements. With many years of experience in the planning, development and implementation of intralogistics solutions, we supply customized systems that are perfectly tailored to the specific needs of your company – regardless of industry or company size.

Smart-FlexDEPOT Classic: In this model, products are stored manually. The goods are placed on the storage conveyor and all relevant data is automatically transferred to the system by scanning the barcode. Continuous stock reconciliation with your merchandise management system ensures that stock shortages are avoided. Retrieval is carried out via an intuitive HMI display or via mobile devices using an app.

Smart-FlexDEPOT Premium: In the Premium model, products are also stored via a storage conveyor, but the system takes over the entire rest of the process independently. As soon as the goods are placed on the conveyor, they are stored randomly and the storage heights are automatically adjusted to make optimum use of the available space. Fully automatic retrieval guarantees maximum efficiency and speed.

Both models offer a high degree of flexibility and easy integration into your existing infrastructure. The Smart-FlexDEPOT grows with your requirements – from semi-automatic to fully automatic solutions – and ensures that your warehousing and order picking are operated at a highly efficient level.

Order picking at top speed: the high-speedDEPOT

The High-SpeedDEPOT is a powerful solution for fast and efficient order picking in sectors such as warehouse logistics, e-commerce and industry. With its high flexibility and modular design, the system can be adapted to different space conditions and requirements. It optimizes the material flow, increases productivity and reduces errors, even at peak loads. Thanks to its simple integration and maintenance, the High-SpeedDEPOT offers a sustainable solution for increasing efficiency in your company.

FAQ:

Which products can an order picking machine store?

An order picking system such as the Smart-FlexDEPOT from AMI can store a variety of products of different sizes, shapes and weight classes. It is specially designed to efficiently store both small and large items and prepare them for picking. The flexibility of the system enables the integration of a wide range of different items, from the smallest small parts to larger goods. Even products with many different geometries, such as round bottles, oval tubes, cans and similar shapes, can be stored and picked without any problems. Storage and picking are individually adapted to the specific requirements of the company.

What advantages do automated picking machines offer compared to manual picking processes?

Automated picking systems such as the Smart-FlexDEPOT offer numerous advantages over manual picking processes:

- Increased efficiency: Automated systems such as the Smart-FlexDEPOT optimize the picking process through fast and precise picking, resulting in shorter processing times.

- Error reduction: Automation significantly reduces the risk of human error, leading to greater accuracy and reliability in order picking.

- Cost reduction: In the long term, the use of picking machines can reduce labor costs, as fewer manual work steps are required.

- Space optimization: The system enables efficient use of storage space, resulting in higher storage capacity and better use of the available space.

- Scalability: picking machines can be easily scaled and adapted to support the growth of the company as requirements increase.

How can an automated order picking system be integrated into existing warehouse and production processes?

The Smart-FlexDEPOT from AMI can be seamlessly integrated into existing storage and production processes. Integration takes place in several steps:

- Analysis of existing processes: First, the existing warehouse and production process is analyzed to determine the requirements and objectives of automation.

- Customized adaptation: Based on the analysis, the system is adapted to the specific circumstances of the company. This includes adaptation to existing IT systems, warehouse layouts and product requirements.

- Simple system integration: The Smart-FlexDEPOT can be integrated into existing warehouse management and production systems via standardized interfaces so that it works seamlessly with existing processes.

- Training and support: AMI offers comprehensive training and support to ensure a smooth introduction and use of the system.

This flexible integration enables companies to increase the efficiency of their existing processes without significantly disrupting ongoing operations.