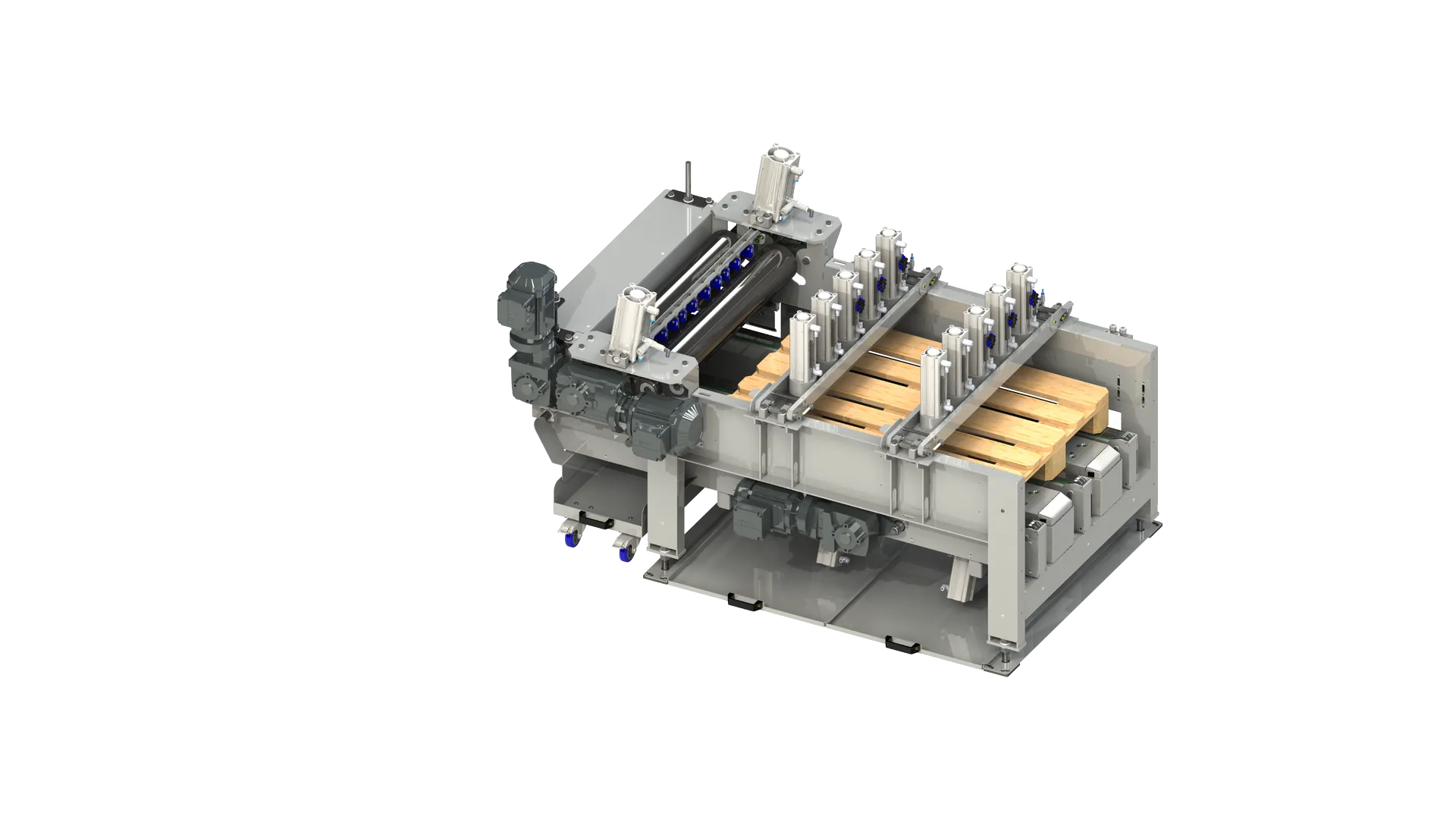

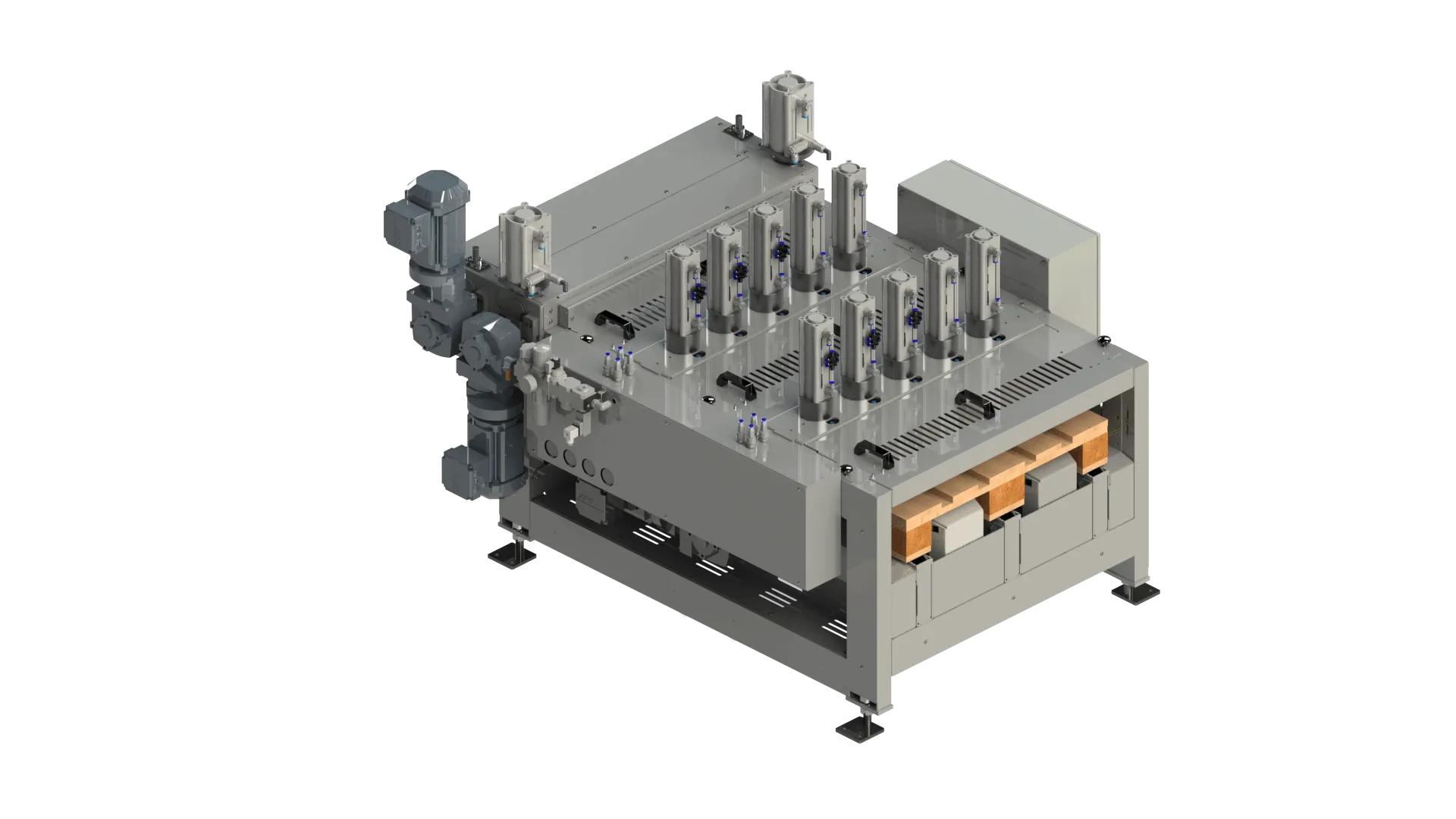

The pallet inspection station – customized quality inspection for pallets

The AMI pallet inspection station is a specially developed system for the quality control and inspection of pallets in intralogistics. It was developed to ensure that pallets meet the highest quality standards and are suitable for use in various logistics processes. The compact, automatic pallet inspection station checks the quality and dimensional accuracy of both delivered and circulating Euro pallets.

Maximum accuracy during pallet inspection

The pallet inspection station offers a comprehensive inspection for cracks, deformations and other defects. It works precisely and efficiently thanks to the use of the latest sensor technologies and automated test procedures. The inspection station can be easily integrated into existing conveyor lines and ensures seamless adaptation of the inspection process. In addition, a test force is applied to each board of the pallet to test its durability. Pallets that are not in order (NIO) are automatically ejected onto a separate conveyor line so as not to jeopardize the material flow.

What makes the pallet inspection station so effective?

High precision

Modern sensors and automated testing procedures ensure precise and accurate testing of the pallets.

Efficiency

Automated testing enables fast and efficient quality control, which optimizes production processes.

Flexibility

The pallet inspection station can be quickly and easily integrated into existing conveyor lines and flexibly adapted to different requirements.

Security

Thanks to the comprehensive inspection, safety-relevant defects are detected and avoided at an early stage.

Longevity

High-quality materials and a robust design ensure a long service life for the test station.

The AMI pallet inspection station provides optimum support for any intralogistics system that focuses on quality and efficiency. The station helps to optimize production processes and increase the safety and reliability of logistics.

FAQ:

Why do pallets need to be checked?

Pallets must be checked regularly to ensure that they meet the required quality standards and are suitable for the transportation of goods. The inspection detects defects such as cracks, deformations or inaccurate dimensions at an early stage, which increases safety in logistics and prevents damage to transported goods. The pallet inspection station ensures this comprehensive inspection and helps to maintain quality standards.

What advantages does a pallet inspection system offer compared to manual inspection methods?

Compared to manual inspection methods, the pallet inspection station offers numerous advantages as it is faster, more precise and automated, which makes the entire inspection process considerably more efficient. Consistency is increased by minimizing fluctuations in the test results. At the same time, time and resources are used more efficiently, allowing staff to focus on value-adding tasks while production processes are optimized.

Which test parameters are recorded during the pallet test?

During the inspection by the pallet inspection station, various parameters are recorded to ensure that the pallets meet the quality requirements. The most important test parameters include:

– Dimensions: Checking the correct dimensions of the pallets.

– Condition: Checking for cracks, deformations, other defects and the absence of elements on the pallet.

– Load capacity: Ensuring that the pallets have the required load capacity.

– Functionality: Checking whether the pallets can be used correctly in the transport process.

How can a pallet inspection station be integrated into existing conveyor lines?

A pallet inspection station can be easily integrated into existing conveyor lines without disrupting the process. The inspection station fits seamlessly into the process and ensures smooth and efficient operation while guaranteeing the quality of the pallets. Integration of the pallet inspection system is simple and can be carried out without extensive changes to the infrastructure.